contents

Integrated Operating Center

- Need and Purpose

-

Background

1) Construction and operation of mid to large CHP plants

2) Rationalization of distributed heat source construction and operation

3) DH network advancement

4) Rationalization of heat source maintenance plan

5) Improvement of plant automation level

Need

1) Establishment of methodical power generation plan and heat operation plan according to demand forecast

2) Monitoring and control of overall operating plan

3) Review of quick operating plan to cope with condition change (urgent order, etc.)

Purpose

1) Maximized income through optimum economic operation

2) Improved reliability of whole system through stable system operation/maintenance

- Functions and Configuration

-

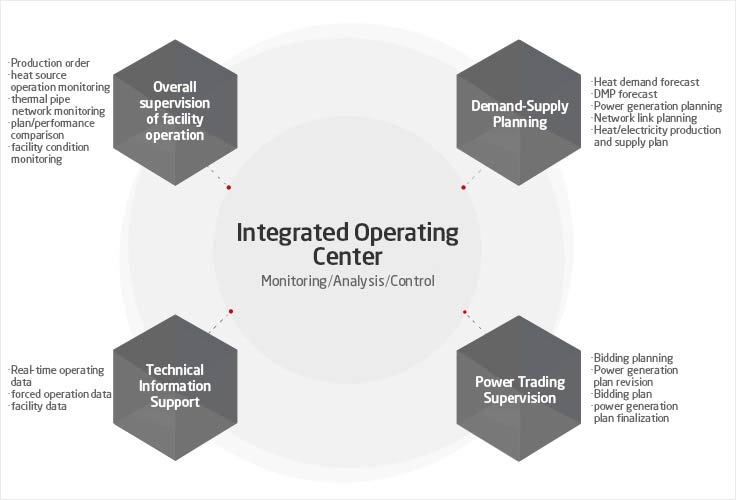

Functions

Configuration

Integrated Operation Center Infrastructure

- Operation room equipment layout (incl. support equipment)

- Hardware selection and internal networking

- Display screen configuration and layout

Integrated Energy Management System

- Economic operation system

·Heat demand forecast system (heat source operating plan)

·SMP forecast system (CHP plant power generation plan)

·CHP plant optimum operation engine development (operation priority/operation mode/power generation)

- Economic operation system

Power Trade System

Information Delivery System

Networking with Redundancy

- Integrated Operation Center ~ Branch (Order and Monitoring)

- Integrated Operation Center ~ (Branch) ~ Distribute Heat Source/Booster Station (Remote Operation)

- Economic Operation Program

-

Structure / Output

![[시장(Database)] - [열 수요예측 Engine],[SMP예측 Engine] - [예측결과DB(FC):SMP가격, 비제약 발전량, 계통제약 발전량, DH Load], [Master DB(MD) : 연계배관망 정보, 엔진기둥, Parameter], [열원별특성치 DB(PS) : 지사별 열원 현황, 열원별 특성치] - [경제운전 최적화 Engine], [What-if 시나리오(DB)] - [열 생산 시설 가동우선 순위 표 : 1순위(생산시설:용인INC,비교지수:114,가동여부:O), 2순위(생산시설:분당CC, 비교지수:120, 가동여부:0), 3순위(생산시설:분당CC, 비교지수:384, 가동여부:0), 4순위(생산시설:서초 PLBWG, 비교지수:483, 가동여부:X)], [연계열량 배분 내용을 시간(1H, 2H), 열 공급량(분당/용인), 연계수급량(분당->용인/화성->동수원)으로 구성한 표], [지사별 열생산 및 공급산정 내용을 시간(1H, 2H), CC, PLB, CHP, 발전량으로 구성한 표]](../img/special/structure.jpg)

Overall Flow Diagram

![[열수요예측, SMP 수요 예측] - [연계운전 최적화, CHP PLANT 운전 최적화, MIP Based Solver] - [지사운전 계획],[발전계획수립, 전력거래입찰, 열원 운전계획] - [연계운전 관리],[급전지시(KPX)],[Feedback(필요시 계획 재조정] / Max, One Cycle Run Times 30 Minutes](../img/special/structure_01.jpg)

Heat Demand

Forecast ProgramMethodology

- Exponential Smoothing Method

- Regression Analysis : Causal type forecast technique (content to be modified)

Demand Forecast Modeling : Pattern Analysis

- Modeling type: Saturated branch/unsaturated branch

- Weather data/Linked heat load/Average load/Daily characteristics (weekday/weekend, etc.)

Accuracy Criteria: Mean Absolute Percentage Error (MAPE) ≤ 5%

Schematic Flow Diagram

![[외기온도, 일별특성] - [Data Bank : 지사 열부하자료, 기상자료] - [Pattern Analyzer : 포화지사 Pattern, 불포화지사 Pattern] - [Daily DH 부하 예측] - [Hourly DH 부하예측] - [CHP PLANT 최적화 Engine]](../img/special/structure_02.jpg)

SMP Demand

Forecast ProgramMethodology and Calculation

- Mixed Integer Programming(MIP) : Future method of KPX calculation

·Improved solution: Latest solution

·Relative longer simulation time needed: Not a problem with improved computer performance

SMP Calculation

Need for SMP Forecast

- Power generation planning and bidding in power trading: Maximization of income from sales at CHP plant (power)

- CHP plant operation prioritization

Schematic Flow Diagram

![[Data Input(수요 Data, 발전기 성능, 제약조건] - [연계운전 최적화(MIP Based Solver, 시간별 각 발전기, 운전비용단가 산출)] - [한계 발전기 결정] - [SMP 예측] - [CHP 최적화 Engine]](../img/special/structure_03.jpg)

SMP forecast error (estimated value): 2% (of KPX forecast)

CHP Plant

Operation Optimization

EngineMixed Integer Programming(MIP) : Objective Function + Constraints

Simplified Linear Approximation

Max. Profit under Constraints : Revp↑&Cost↓

CHP Plant

Optimization FunctionsCHP plant power generation calculation: Linear approximation

Modeling function list

Heat Allocation

OptimizationConstraints of heat allocation optimization: DH Network

- Benefit Analysis

-

Qualitative Benefit

AnalysisEconomic Operation and Production Cost Saving

- Operation mode optimization to enable flexible response and production in the power market

- Optimum production of heat and electricity and supplied heat adjustment linked with optimum production to save the production cost

- Efficient facility operation to increase the operability rate and lower the investment on facility

Improvement of Manpower Operation Efficiency

- Manual work minimization to maximize manpower utilization

- Training using simulator engine to improve the operating personnel capability

DH Network Stability / Safety Improvement

- Minimization of human error to improve stability and safety of system operation

- Predictive Event Analysis to prevent accidents and improve quick response capability

Quantitative Benefit

AnalysisProduction Cost Saving

- Efficient unit commitment to reduce the heat production cost

- Efficient linked operation to reduce the heat production and supply cost

Increased Income from Sales

- Operation mode optimization to increase income from sales of power

- Effective bidding strategy to increase sales of power